D&S Como Visit October 2025

Durango & Silverton Como Visit Oct 6-8 2025

Right on the heels of our successful summer work season we hosted our D&S teammates for some KMR #4. work. This also enabled additional onsite work to be completed. Special thank you to Sam Kunugi & Dan Silbaugh for leading the work effort!

The Boiler riveting is complete! Both the first to second course, and the first course to the smokebox. It became apparent why railroads typically removed boilers from locomotive frames to do much boiler work. There’s not much room to work around the frame with the rivet gun, so we had to do some of them with an air buck and a bracket welded to the frame to hold the air buck

In order to rivet around the bottom of the boiler, we had to remove the spring packs from the #1 and #2 drivers. In the following photo you'll see the spring pack on the #3 driver, but you’ll notice that the spring packs are missing from the first two drivers, and the spring rigging is entirely unlaced. One thing this gave us the opportunity to do was to swap the springs from the left to the right side, to see if that corrected the lean the locomotive has. Good news: the spring packs are all good. Bad news: the locomotive still has a lean, so the suspect is still the trailing truck as a culprit.

The riveting was our big goal for the week, and we accomplished that. The front tube sheet was not test fit, but we have a plan for fitting it (and most importantly locating the dry pipe hole in it) that should be faster - and also doesn’t require the D&S crew to locate the hole.

We got quite a bit more done. We turned two 10’ 1/2” steel rods Tom Lawson picked up into a whole bunch of new cellar retainers.

Bob Peterson drilling the holes with the milling machine (the milling machine made quick work of our little assembly line).

An original cellar keeper for reference, and our new set on display.

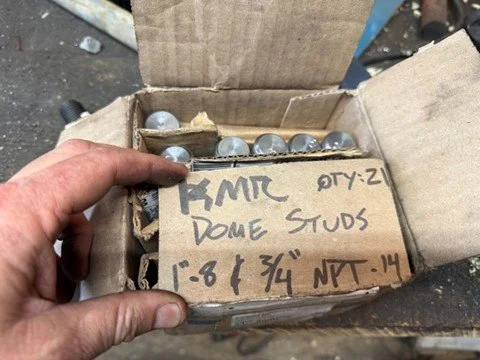

We received the new steam dome studs that the D&S machined on their CNC lathe. These have a tapered thread that we will re-tap into the steam dome, and then a normal straight thread sticking out that will bolt the dome cover on. There is no photo of it, but Bob Peterson, Tim Clay & Dan Silbaugh used our new Mag Drill to whip up a fixture to drill/tap the steam dome bolt circle,. Here are the dome studs - which we will install after we don’t need to climb in and out of the boiler through the steam dome cover again.

Lastly, we received the oil firing valve quadrant so that we can start fabricating the oil firing controls. It’s hard to understate how nice this assembly feels to operate. We are fabricating a bracket to mount the quadrant to the boiler. When it’s mounted to the boiler this is one of the controls the fireman will need to use an awful lot.